Hannay Reels has been committed in solving our customers’ issues for over 85 years. While their story is ever-evolving and this philosophy remains the same, and it’s what has helped them to grow into a strong global business and the #1 reel manufacturer.

Their goal is to provide customers with most durable and well-engineered reels in the industry. They have an unwavering commitment to listen to the needs of their customers and respond by crafting high-quality products that perform safely, efficiently, and economically.

Hannay Reels research and development is dedicated to innovation and finding new ways to improve customers’ businesses. Their custom department is on the forefront of design capability, producing quality hose and cable reels that meet the precise requirements of the many industries they serve.

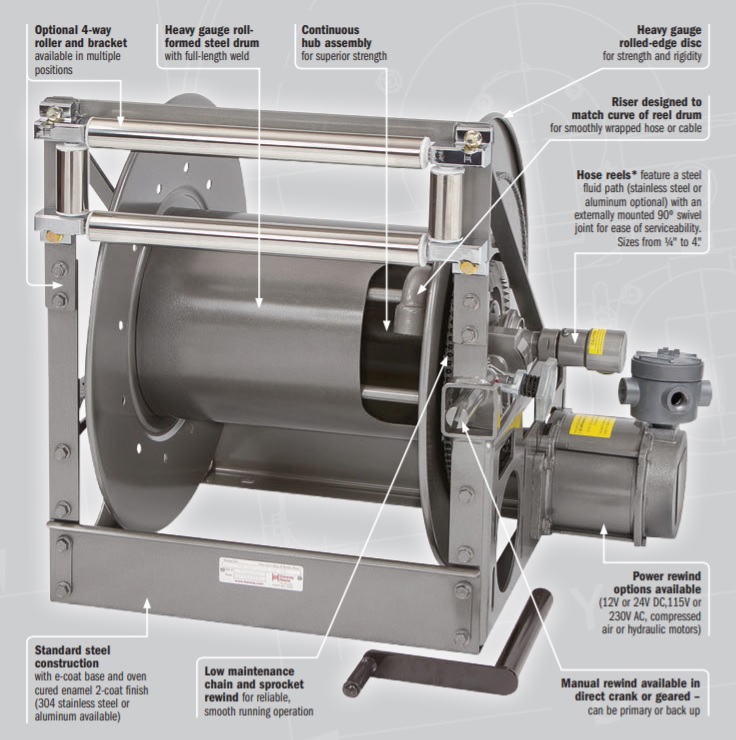

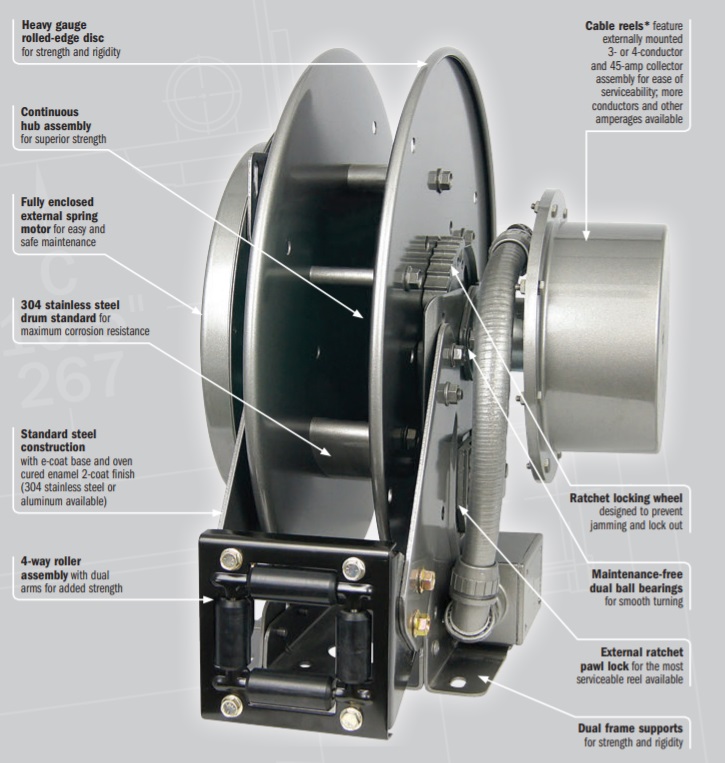

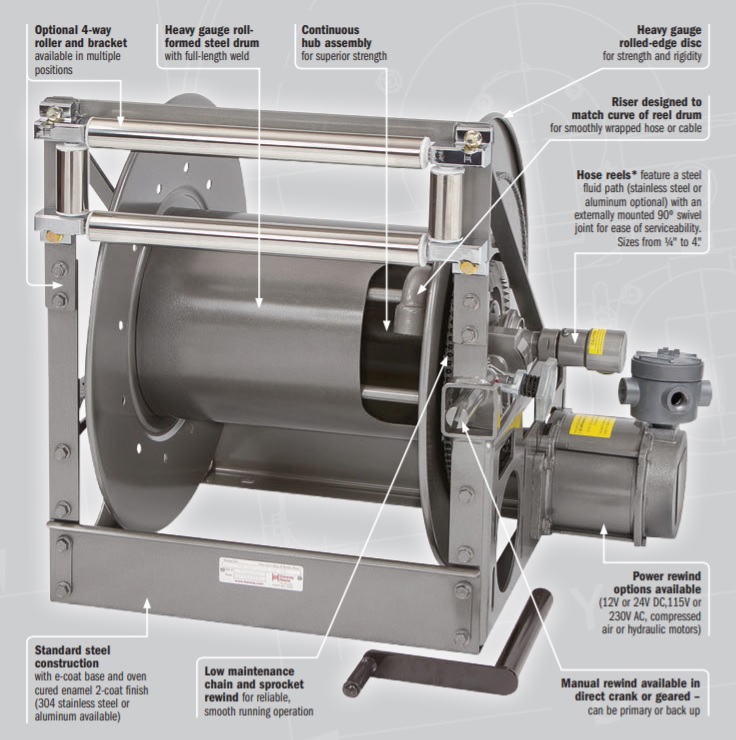

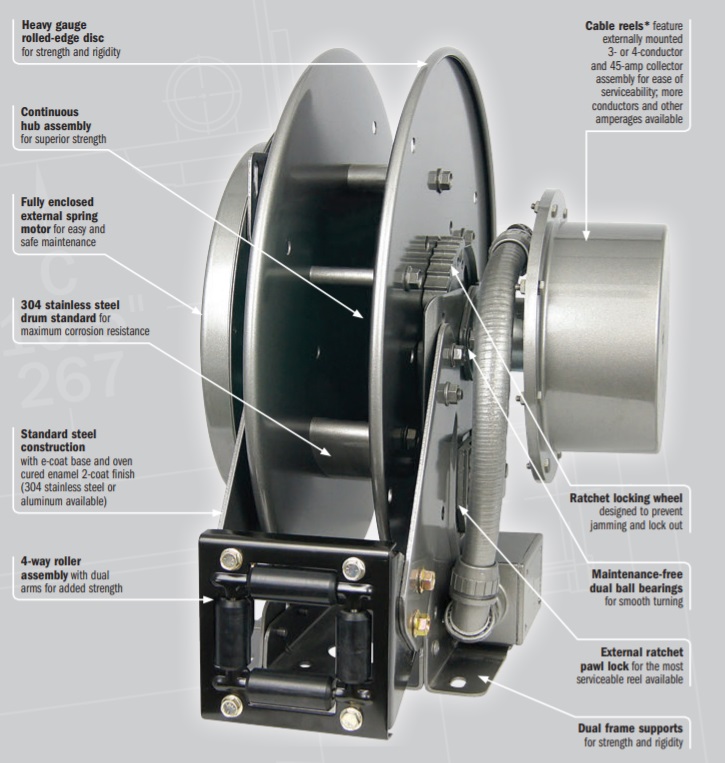

Anatomy of Hannay Hose Reels & Cable Reels

MANUAL/POWER REWIND CABLE AND HOSE REELS

SPRING REWIND CABLE AND HOSE REELS

With thousands of models and extensive custom capabilities, Hannay Reels boast a steadfast commitment in delivering solutions for every application, whether big or small. They offer design and construction advantages that contribute to a premium quality that customers in the toughest jobs demands which including the followings:

- Heavy-duty design and reels construction

- Dual bearing and dual frame support which is standard on all models

- Heavy-gauge steel reel frame

- Sealed axle bearings for smoother operation and longer life span

- One-piece axle hub and fluid path assembly for hose reels

Select the right Hose Reels or Cable Reels from our E-Store now.